Technology

Most experts on lead acid batteries agree that the hardening of lead sulfate (Pbso4) in lead acid batteries among the first cause of failure and 70-80 % of batteries are failed due to sulphation. Other’s view the evolution of an amorphous corrosion layer in the positive plate, as a cause of failure in the batteries.

Green lava power-plus / XTR Solution helps to sustain healthy, soft, moisture and porous lead sulfate (Pbso4) particles and special Rejuvenator/Charger uses patented technology to de-sulfate the lead plates using pulse current waves.

Our years of experience in the field of lead acid battery reconditioning suggest that in order to recover the lost potentials of any failed lead acid battery one needs access to a battery power recovery technology that is reliable, efficient and effective. We have accomplished this by developing a technology that is grounded in the science of electro-chemistry.

From a chemical point of view we have developed a solution that recovers the lost potentials of any lead acid battery caused due to Sulphation buildup. This chemical reaction can be understood in two parts. The first part of our chemical process is to dismantle the hard lead sulfate crystals (PbSO4 or Sulphation buildup) as the battery gets re-polarize (charged). The second part of our chemical process is to allow re-assembly of the lead sulfate particle in a molecular structure that will not harden again. This occurs during discharging of the battery as it is under a load or discharge.

We also use electricity to accompany our chemical process of desulphation. Our special battery conditioners are built to help dismantle the hard lead sulfates. All our special battery conditioners are made to be easy to use, to handle more than one battery at the time, to manage different types of batteries (flooded, Gel, AGM, VRLA), and to yield results.

Our battery recovery technology is named “Genesis Battery Power Recovery Process”. This process follows scientific understanding of the electrochemical functioning of a lead acid battery. It is also based on our theory of the causes of passivation in a battery. At the core of this theory is our understanding that to dismantle hard lead sulfates crystals (Sulphation or PbSO4) one has to create an electro-chemical fracturing process that recovers the potentials of the battery at the molecular level where the lead sulfates formed.

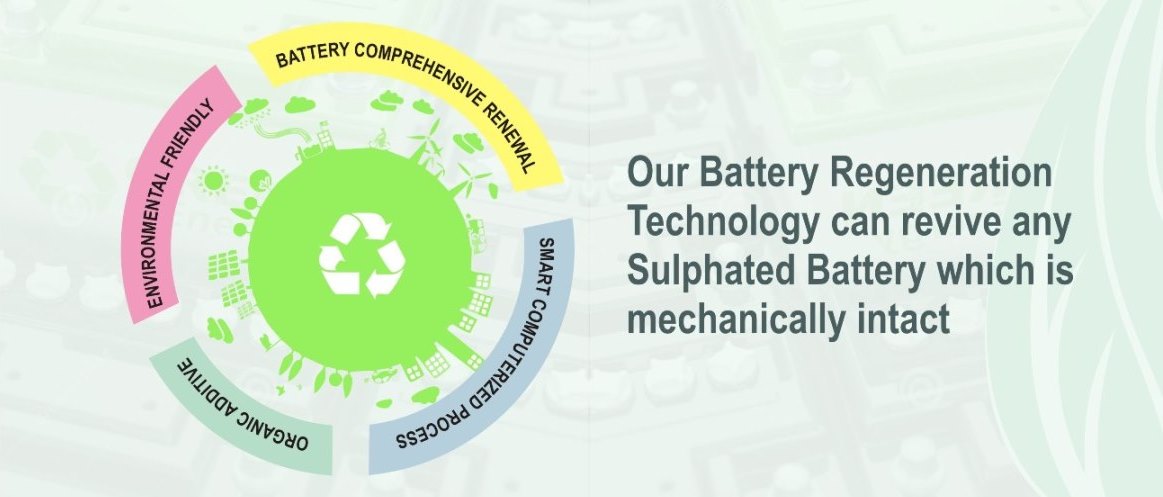

The Genesis recovery process is our methodology based on a procedure of four steps. In order to use it we had to develop technology along two dimensions: electronically and chemically. Electronically we developed the X-Charger and the Genesis; chemically we developed our battery desulfating compounds, Power-Plus Automotive and Power-Plus Industrial, both environmentally friendly agents. We also had to develop testing procedures that yields reliability, ease of use, quickness, and quality of reconditioning outcome.

Our power recovery technology for secondary batteries is founded on a procedure that we called the Genesis Battery Power Recovery Process. This methodology was designed to follow strict scientific principles of electrochemistry of lead acid batteries. The overall purpose of the methodology is to recover the lost potentials of any lead acid battery in any state of health, including those considered to be scrap, or spent, and out of service in any state of charge. Batteries can be flooded or sealed, AGM, Gel, and VRLA of any brand, size, voltage, amperage, and any manufacturing age. The main characteristic required for success is that the batteries be mechanically intact inside.

This method includes the following four steps:

- Screening― This step is for identifying batteries not good for reconditioning covers visual checkup and health checkup of batteries.

- Regen Diagnostic ― This step is for to conduct various tests to access the battery condition for rejuvenation .Diagnostics will allow identifying those batteries that pass the screening procedure but are still not qualified for the desulphation charge.

- Recovery & Charging ― The charge function are designed to de-sulfate and recover the lost capacity of all types of lead acid batteries. The combination of charger and solution restore five potencies in the battery and make healthy .These potencies are –Voltage, Internal resistance, specific gravity, Capacity & CCA.

- Final Quality Control Test –This step to conduct various test & technical parameter ,required for battery at final stage before to put the battery is service use & ensure that battery are capable to give the service life on its application.